Each year, between 700,000 and 1 million patients fall in a hospital in the United States, according to the Agency for Healthcare Research.

About a third of those falls result in an injury to the patient. Sadly, about 11,000 of those falls lead to deaths. The agency estimates that non-fatal falls in adults 65 years and older cost about $50 billion each year, while fatal falls average a cost of $754 million each year.

Companies making high-quality hospital beds are Umano, Span-America and Oxy-Mat. All are leaders in the industry, well respected and available through Keckler Medical.

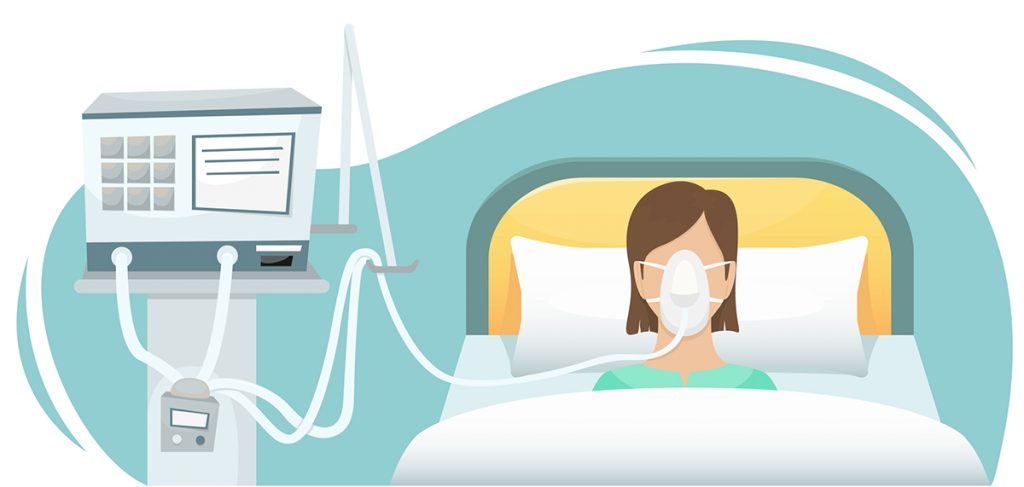

Umano’s beds are used in many health care settings — from high-acuity critical care through long-term care and even inpatient psychiatric or correctional health. They are designed to maximize fall prevention and infection control, while being easy to use for caregivers and the lowest total cost of ownership for the hospital’s budget.

Span-America and Oxy-Mat both offer mattresses that reduce the risk of pressure ulcers and skin shearing.

Span-America’s mattresses incorporate low air loss and pressure redistribution technology where body length air chambers slowly inflate and deflate to reduce pressure points and turn the patient every 12 to 15 minutes. Its Geo-Mattress® UltraMax™ reactive surface with 3-Dimensional Zoning™ offers protection to the seat section against “bottoming out” even during repeated head and foot of bed elevating. The UltraMax™ bi-directional stretch cover prevents heels, hips and shoulder blades from “digging into” the surface. Instead, patients are gently guided back to the original position following head of bed elevation.

The Oxy-Mat mattress has air pockets in foam that disperse pressure points “on the bony prominences” of the body. The unique design reduces the vertical and horizontal shear forces that lead to pressure ulcers in the sacrum, scapula, trochanter, ischium, head and heels. The mattress helps the patient’s own body to naturally optimize deep-tissue blood oxygen values in anatomical areas at the greatest risk of pressure injury development.